Gas-cooled MIG/MAG torch

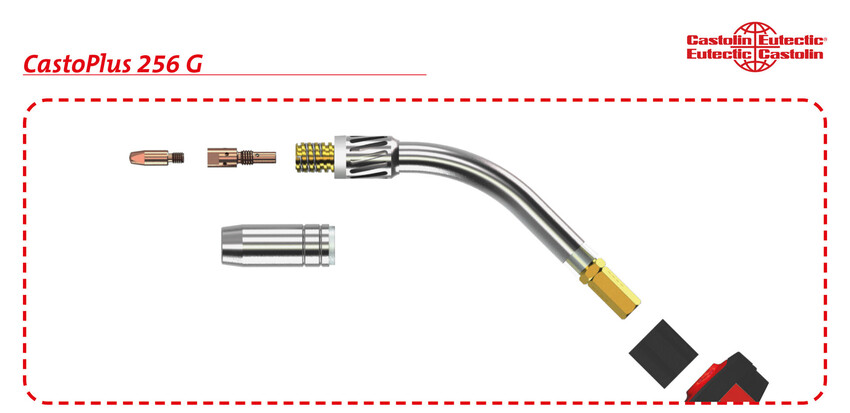

CastoPlus 256G

Gas-cooled MIG/MAG torch

230A/60% ED, Euro central connection, pistol grip,

M6*28/1.0 mm contact tip, conical 14.5 mm gas nozzle

The MIG/MAG torch is a hand-held tool used in the MIG/MAG welding process (metal inert gas/metal active gas). It plays a crucial role in supplying the required heat, shielding gas and welding wire to produce a welded joint. Below you will find an overview of the MIG/MAG torch and its functions:

Heat supply: The MIG/MAG torch is used to supply heat to the workpiece. It is connected to a welding power source that supplies the required electrical current. The torch has a contact tip or nozzle through which the welding arc is formed. The electric current flows through the contact tip and creates an arc between the tip and the workpiece, which generates the heat required for the welding process.

Shielding gas supply: In MIG/MAG welding, a shielding gas is required to protect the molten weld pool and the weld bead from atmospheric contaminants such as oxygen and moisture. The torch is equipped with a gas nozzle or diffuser that directs a stream of shielding gas, usually a mixture of argon, carbon dioxide or a combination of both, onto the welding area. The shielding gas forms a protective atmosphere around the arc and the weld seam, preventing the formation of unwanted oxides or other defects.

Feeding the filler wire: In MIG/MAG welding, a consumable filler wire is used to feed material to the weld seam and create the weld bead. The MIG/MAG torch has a wire feed system that draws the filler wire from a spool and feeds it through the torch. The wire feed mechanism is often located in the torch handle or is connected externally to the torch. The wire is fed through a contact tip where it is melted by the heat of the arc and applied to the workpiece, creating the weld bead.

Torch controls: MIG/MAG torches are equipped with various controls and functions that allow the operator to set and regulate the welding process. These controls include wire feed speed control, voltage control and gas flow rate adjustment. The operator can fine-tune these settings to achieve the desired welding parameters such as weld bead size, penetration and overall weld quality.

Ergonomics and handling: MIG/MAG torches have been designed with ergonomics in mind to provide the operator with comfortable handling and ease of use. They usually have a light and balanced design with a comfortable handle and trigger mechanism. Ergonomic torch designs help to reduce operator fatigue during prolonged welding operations and improve overall welding efficiency.

Torch consumables: MIG/MAG torches require regular maintenance and replacement of wear parts. This includes contact tips, gas nozzles, diffusers and other components that can wear out or become worn during welding. The correct selection and installation of torch consumables is essential for consistent welding performance and to avoid problems such as porosity, spatter or erratic wire feed.

Specification

| Code | 767673 |

|---|---|

| Category | MIG/MAG torch |

| Price excl. VAT | 73,41 £ |

| Price incl. VAT 20% | 88,09 £ |

| Availability | within 5 to 10 days |